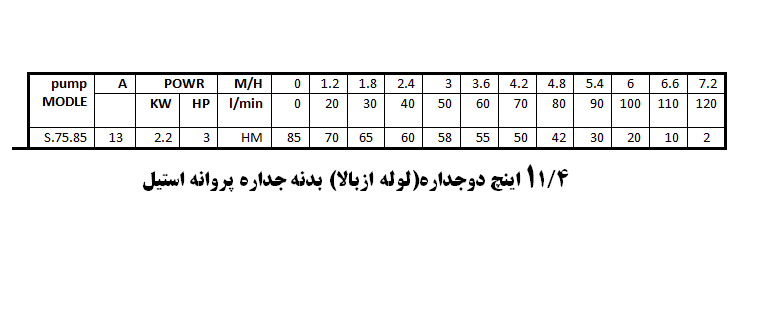

Single-phase / three-phase / steel impeller / double-walled subersible pump

Single-phase / three-phase floor pump / steel impeller / double-walled industrial machine and It is semi-industrial, which can be transmitted by creating a centrifugal force Fluids with different viscosities, including water The Submersible pumps is an industrial and semi-industrial device that, by generating centrifugal force, can allow the transfer of fluids with different viscosities, including industrial water and sludge, to arbitrary points. The nature of these pumps is done under certain conditions, and everyone has a certain level of expectation. Some may expect slurry to be raised from a depth of 15 meters from these pumps, and some will use only for short distances, such as two to three meters. This suggests that the size of the submersible pump and the components used in them have an important impact on our final selection. In water supply systems, pressure sources are also commonly used, which can be supplied by the motie pump company. One of the most famous brands of under pressure, can be referred to the tank under the pressure of the pump. Resources under pressure Also used which you can also find it from Negin online store Prepare. One of the most famous brands of pressure source, can be Hamak Iranian pressure tank and Tank under pressure from Italy Cited.

The main task of the floor pump is to create a vacuum and create a suction force for the fluid, which can allow the fluid to rise from a piping system. Capillary property is one of the features that has a direct path in creating floor pumps and sludge pumps and even changes their performance. Motor performance in these pumps is of particular importance and can determine their efficiency in various areas